Confirm the center position of the hinge of the back door hinge

Before installing the design of the back door gas spring, the completed data should be verified. It is necessary to confirm whether the two hinges of the back door are coaxial; whether the back door interferes with the surrounding of the vehicle body during the whole process of rotating along the hinge axis; whether the installation space of the gas spring is fully reserved. A

Determine the total mass of the back door and the location of the center of mass

The total mass of the back door is the sum of the quality of multiple components made of metal and non-metal materials. Including back door sheet metal parts, back door glass, rear wiper system, license plate lights and decorative panels, rear license plates, back door locks and back door interior panels, etc. Under the premise of knowing the density of the parts, the weight and centroid coordinate points can be automatically calculated using the CATIA measurement inertia command.

Determine the location of the installation point of the gas spring on the back door

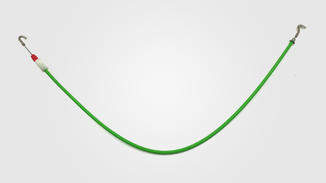

The installation point of the gas spring here theoretically refers to the center of rotation of the ball head at both ends of the gas spring. The gas spring is generally installed with the piston on the top and the piston rod on the bottom. The connection between the gas spring and the inner panel of the door must be transitioned by a bracket mounted on the inner panel of the back door to allow for the opening of the outer diameter of the piston and the space for movement. There must be a reinforced nut plate on the inner side of the door inner panel to install the gas spring bracket. The strength of the back door nut plate and the bracket and the rigidity of the back door must meet the requirements of the gas spring maximum stress. The installation position of the gas spring on the bracket is the position of the upper installation point of the gas spring. The size of this position from the center of the hinge shaft affects the supporting force required by the gas spring. Under a certain load torque, the size is reduced by 10%. The support force will increase by more than 10%, and the stroke of the gas spring will change accordingly. The design goal should be to reduce the supporting force required by the gas spring as much as possible while satisfying the opening of the back door and easy access on both sides of the back door, because excessive support force will increase the manufacturing cost of the gas spring and the rigidity of the back door Claim.

Determine the opening angle of the back door

According to ergonomic analysis to determine the opening of the back door. At present, there is no regulation on the height of the ground from the bottom edge of the door where the back door is opened to the maximum position. According to the convenience of people standing on the ground, when the general design is opened to the maximum position, the height of the lowest point of the lower part of the back door should be about 1800mm from the ground to determine the opening angle of the back door. This design is based on not only considering that the head of the person is not easy to touch the lowest point of the lower part of the back door, but also to take care that the hand can easily reach the handle when the door is closed. Due to the different height and structure of the car body, the opening angle of the back door of each car model is also different, roughly between 100 ° and 110 ° from the vertical direction. At the same time, the maximum opening angle of the back door should be less than the maximum opening angle that the hinge can reach; the gas spring runs to the end of the stroke and has a buffer mechanism to avoid damage to the components.

简体中文

简体中文