The metal components of automotive control cables do require special attention. These metal components, such as conductors, shielding layers, etc., play a crucial role in automotive electrical systems. They not only affect the performance and lifespan of cables, but also directly relate to the safety and reliability of automobiles.

Firstly, the conductors of automotive control cables are usually made of highly conductive metal materials, such as copper or copper alloys. The selection of these materials needs to ensure that the cable can automotivery the required current while having good conductivity and corrosion resistance. Therefore, in the design and manufacturing process, it is necessary to strictly control the material, specifications, and process of the conductor to ensure that it meets the requirements of the automotive electrical system.

Secondly, the metal shielding layer is also an indispensable component of automotive control cables. The main function of the shielding layer is to prevent electromagnetic interference and signal attenuation, ensuring the stability and reliability of the signal transmitted by the cable. Inside a automotive, the electromagnetic environment is complex and ever-changing, and various electrical devices and wiring harnesses may interfere with each other. Therefore, the selection and design of metal shielding layers need to fully consider electromagnetic compatibility and shielding effect to ensure that cables can still function normally in harsh electromagnetic environments.

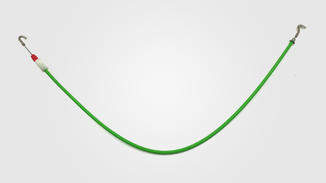

In addition, special attention should be paid to the connection and fixing methods of metal components of automotive control cables. Due to the vibration and impact generated during the driving process of the automotive, if the metal parts of the cable are not firmly connected or not fixed properly, it may cause to poor contact, short circuit, or even breakage and other faults. Therefore, in the design and installation process, reliable connection methods and fixing devices need to be adopted to ensure that the metal parts of the cable can be firmly connected together and maintain stable performance under various working conditions.

简体中文

简体中文